There is a side to the 3D printing “hobby” to which I have not paid much attention. It does not focus on printed item design at all. Printed product design is a totally different side of the hobby.

I am not inferring that a hobbyist can not enjoy and pursue many sides to an avocation. All that requires is enough time.

This “other” side to which I refer, is the technical process involving the printer hardware and operational software systems. Maybe that is two more sides. My point is that it has almost nothing to do with form and design of the object to be printed.

Ham Radio

My amateur radio hobby is much the same. There are ham operators who concentrate on the operation of making contacts and using the radio equipment. No desire to design or make their own radio hardware. The fun is contests in which they make contacts.

Other hams are into circuit design and all things technical. Building personal or published circuits from scratch. This is almost a lost art. But there are still hams building radios and station accessories from component parts. We are federally tested and licensed and permitted to do so.

_… _._

Many hobbies have these two faces. 3D printing is no different.

I buried my head in the sand a bit and have concentrated on the plastic things I make as the main goal of my activity.

I think it is because I have been thinking of the youth (grade school age) getting involved with 3D printing as a career. The best career path in my opinion, should be the engineering involved in product design using additive manufacturing. Not simply how to operate the machine.

BUT…

As simply a hobby to enjoy, there is nothing wrong with just doing what one enjoys. If it is customizing the hardware and tweaking for more speed, That’s fine with me. It’s accomplishment of that next goal that satisfies.

It’s probably not a career path but for most people, that’s not the purpose of a hobby.

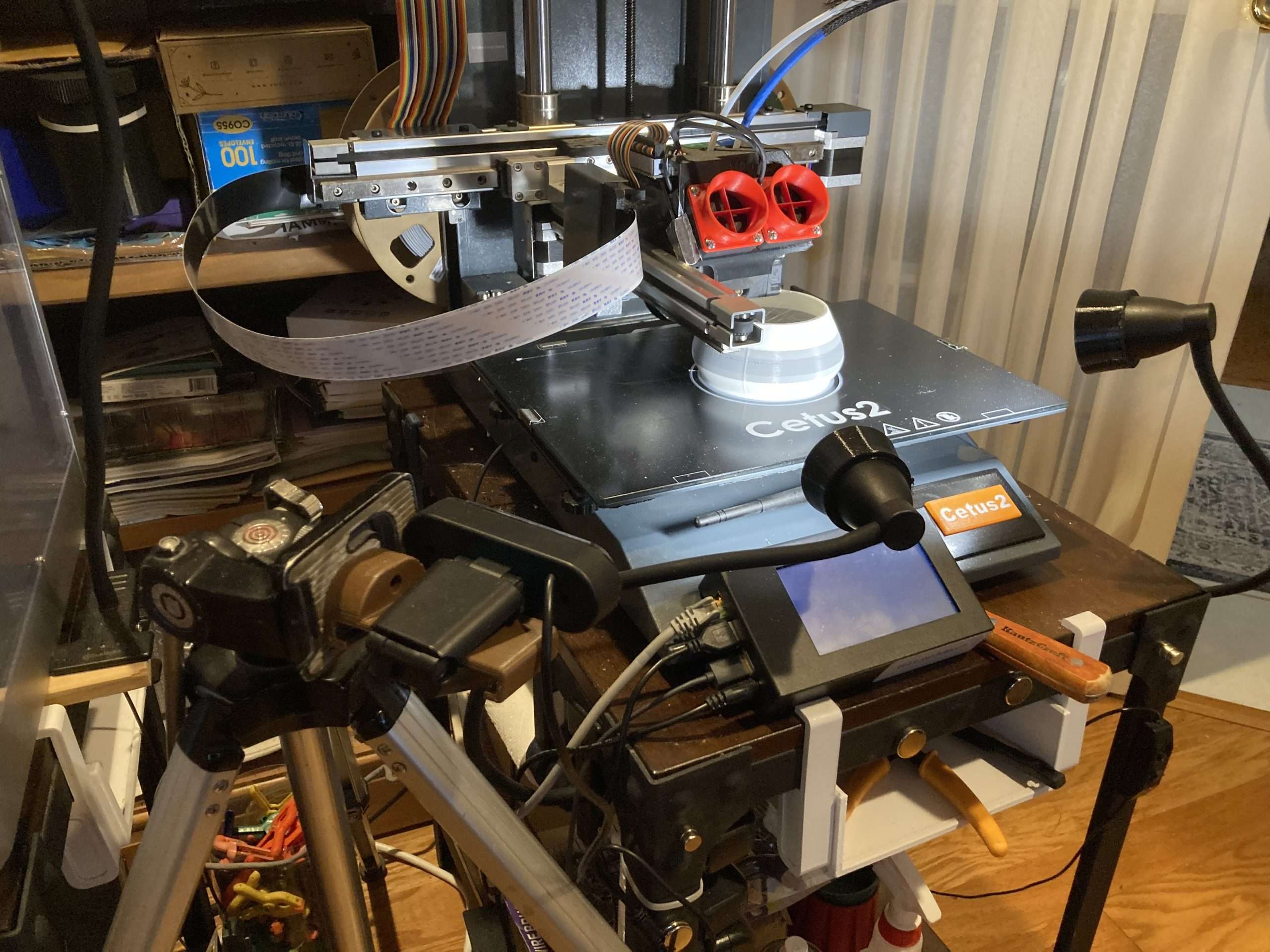

I am playing with new software. OrcaSlicer with Klipper on a CETUS2. Far more complicated than is necessary for good prints. But it puts literally everything about the hardware control at one’s finger tips (on the keyboard).

It DOES NOT make the printing process easier and that is not the intent. It’s a paradise for the control fanatic. I have been spending a bit more time on that side of the fence. I understand, this is mostly what some people desire.

Off Key

I have seen a sub-culture of computer hardware hackers who get great enjoyment from building custom computer keyboards with “hot swappable” keys and flashing color change lighting under them.

Hey! If they like it, then fine. It just not building a flashing keyboard that gets me excited. Ha!

Back to 3D printing…

So… I don’t feel a need to master every new slicer or bit of 3D hardware on display. It IS fun to see what gets other folks excited about their side(s) of the 3D printing hobby.

Maybe I will get the tech bug too. But I know I have no goals of trying or mastering everything. Just doing the things I like keeps me busy enough.

I have several CAD systems I can use for product design and 4 slicers and at least 4 different operational types of FDM and RESIN printers with which to spend my time.

A killer whale and a clipper ship are just something new in control technology…

Leave a Reply